[from the editor: Doug snuck from the Bridgeport to the window to send this as Morse code using sparks from the TIG welder]

OK folks, here it is, the update that you have been waiting for, wherein we report on the reality of parts actually being made and structures that are coming together. SO much stuff has coming on-line in the past week. Let me tell you about it…

KICKSTARTER

As you may well know, our Kickstarter was more than successful, we grossed $16.3K, which nets us about $11.5K after the fees and rewards are paid for. This lets us meet all of our initial goals AND our stretch goals. So a great big THANK YOU goes out to all of you who helped make this possible. We are gathering data from rewardees and are working on finding suppliers for all of our rewards.

TRANSPORT TRUCK

We now have a 24-foot long box truck that appears to be in pretty darn good shape within which we will transport all of our equipment, parts and gear to the Playa. We will have some extra space on the truck, so if you are getting out there early and want your gear to arrive with you, get in touch and we will sell you some space. In the coming week we will be having a diesel mechanic going over it, changing fluids and replacing/repairing the few small things that it needs and generally making sure that it is more than road-worthy for the trip.

WOOD WORK

Last Saturday Mark H, Chuck I, JfM & I headed out to Ashby, Massachusetts to start in on the carpentry for the wooden tower top. There were six 8” x 10” x LONG beams that we turned into 7-3/4” x 10-foot long hexagonal columns, and all of the other 5-sided railing balusters and posts were made and all of the rafter truss components were cut to size and band-sawed to shape.

The week before, I cut out 8 of 11 of the sheets of plywood on the CNC router. This comprised the upper tower floor, the railings, half of the railing panels and 4 of the cupola sunshade end-caps.

During this past week, the floor decking was fabricated and assembled and the floor is all together now. The MONSTER columns have been chopped and mortised and had all of their final cuts made onto them. The balusters had their final sanding and all of the plywood parts had their edges cleaned up with a round-over bit on a hand router.

STEEL TOWER

For the steel tower, 5 of 7 of the rings were cut, ground, drilled and welded together. The components of the other two have been cut and ground. Some of the more difficult cuts are pictured below:

All 24 of the mid-section flat bars have been twisted 70-degrees along their 12+-foot length via a contraption made up by Max E. that worked fantastically. They are now marked for drilling and that will be finished by tomorrow, then we can make our fist attempt at putting a section of the tower up and see what we get.

All of the flat connecting plates that will hold the bottom section of the tower together were finished and delivered to us by Tom W of Limerick Machine up in Maine and we have begun cleaning them up and welding them where they belong.

The last pieces that still need to be made have had their designs finalized and the material is here in the shop and they will be finished this week.

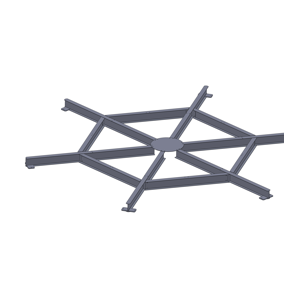

I-BEAM BASE

We have re-designed the base that sits on the Playa since our original plan of burying the base is no longer a viable Playa option. We re ran our wind-load and structural analysis on the widened tower and the new base and are happy with it. The new base will be made up of an I-beam hexagon that the tower will sit on and six, 10-foot long radial outriggers that will be staked into the Playa with up to 42, 30-inch long, 5/8” diameter steel stakes. Additional holding forces will be generated by up to 20, 6-inch diameter, 48-inch long screw-anchors that will be driven into the Playa and attached to mounting points on the tower base by turnbuckles.

SPARK CHAMBER

Our small test Spark Chamber is assembled as well as our power supplies, and the HV circuits are near completion of the testing phase. We expect to be running tests under power and within a gas-filled environment this week. Last week we received the 18” diameter, 21” tall glass cylinder that the Spark Chamber will reside in, as well as the scintillator plastic that will be the front end of the Muon coincidence detector. The PhotoMultiplier Tubes have been tested and oscillations in the power Supplies for them have been figured out. The thyratron power supply has been bread-boarded and is being tested out right now.

CLOTH SKIRT

The cloth skirt that will wrap the bottom third of the steel tower has been cut to rough size and primed with two coats of white and is ready to be finished upon completion of the lower section of the steel tower so it can be fitted to it exactly. Then we will fold over the edges, sew the seat belt edging to it and put in all of the edge grommets. After that there will be painting of the final design and much celebrating.

LIGHTING

As for our amazingly complicated lighting extravaganza, the hundreds of meters of LED strips have arrived. The lighting architecture has been nailed own and the connectors, power-supplies and other assorted bits are on order. The programming has begun and we have a simulation that you can view here:

Cosmic Praise lighting MIDI integration test from Dewb on Vimeo.

As soon as the center section of the tower is built, which should be by the middle of this coming week, we will be able to start installing the bulk of the LED strips and testing them and the control programs and associated wiring power supplies etc. A design for a mount for the LED strips has been designed and tested and it looks like it will work fine, so those will be fabricated this coming week as well.

The lighting on the wooden tower top will be able to begin to be installed by Monday. At this time as well, our final locations and mounts for such things as power supplies, vacuum pump, gas bottles, power and data distribution hubs, other assorted electronics and etc. can be finalized.

EARLY/LATE CREW

The early crew is pretty much filled out, but we are still looking to fill out the late crew for take-down and Leave-No-Trace (LNT) considerations. Sharon K has set up a sign-up sheet for volunteers for daily Matter-Out-Of-Place (MOOP) sweeps. Seeing as we are right in Center Camp, the potential for a MOOP disaster is pretty high. So, in order to not absolutely DESTROY the late crew we would like to make sure that we are keeping on top of this during the event itself.